Pozor! Nacházíte se v archivu starých webových stránek Národního archivu. Aktuálnost informací ani validita zdrojového kódu nejsou zaručeny! Pro přístup k aktuálním webovým stránkám Národního archivu klikněte sem.

|

STUDY OF THE EFFECT OF DRYING METHODS ON THE PHYSICAL CHEMICAL AND MICROBIOLOGICAL PROPERTIES OF VARIOUS KINDS

OF PAPER

|

National Library of the Czech Republic, Prague

State Central Archives in Prague

January 2003

The destructive floods in Prague and its surroundings in August 2002 inundated a number of archives, libraries, museums and central bodies of the state administration. Most of the documents affected by the floods were rapidly frozen and stored in the Mochovské mrazírny a. s., středisko Kladno (Mochov freezing plant, Kladno center). On August 29, 2002, the State Central Archives in Prague held a meeting of representatives of the institutions affected by the floods. One of the outcomes of this meeting was the creation of a working group, which would test the individual technologies of drying frozen documents from the standpoint of their effects on the physical chemical and microbiological properties of paper. The State Central Archives in Prague and the National Library of the Czech Republic are responsible for this project.

The submitted study describes the testing of some drying methods and their effects on selected types of paper. Thus, the results cannot be automatically applied to other types of material. It is planned that this basic study will be extended next year to include other aspects that have been discovered (e. g. the effect of freezing on the properties of the paper, artificial ageing of dried samples, drying of tracing paper, photographs, collagen materials, etc.).

Knowledge of the effect of the drying technology on the properties of the paper support is one, but not the only, piece of information that is essential for responsible choice of the most suitable drying methods.

Tab. 1 summarizes all the information required for this selection. A method can be responsibly selected and recommended only on the basis of this information

Tab. 1: Essential information for selection of drying methods

|

Drying |

Price |

Output |

Operating Costs |

Work load |

Damage |

Other*) |

||

|

Physical |

Aesthetic |

Microbial |

||||||

|

Lyophilizace |

☼ |

☼ |

☼ |

|||||

|

Vacuum |

☼ |

☼ |

☼ |

|||||

|

Vacuum packaging |

☼ |

☼ |

☼ |

|||||

|

In the air |

☼ |

☼ |

☼ |

|||||

|

Humid air |

☼ |

☼ |

☼ |

|||||

|

Hot air |

☼ |

☼ |

☼ |

|||||

|

Microwave |

☼ |

☼ |

☼ |

|||||

*) In decision-making, it is necessary to know the volume of documents that can be dried by the individual methods.

Hot-air drying

Hot-air drying is carried out in a chamber intended for baking lacquers and paints with temperature regulation. The temperature attained an average of 115 °C (variation from 100 to 120 °C), with a drying time of approximately 18 hours. The folded paper sheets were placed vertically in mobile wire carts with shelves and were separated by aluminium plates at a distance of approx. 0.5 cm, to accelerate distribution of the heat. The method is used exclusively for documentary material.

Lyophilization - vacuum sublimation

The lyophilization method was tested on the "Alpha 1-4" laboratory equipment borrowed from the Pragolab s. r. o., Prague company. The equipment is manufactured by the German Christ company. During the process, the temperature in the chamber varied between - 12 and - 18 °C at a pressure of 2 mbar; the temperature of the freezing space was - 56°C. The paper volumes were dried in the closed position and bound with a cord to prevent deformation. In the high vacuum, the water vaporized directly from the solid phase - ice - during the process. The paper is completely dried in 5-10 days, depending on the thickness of the volumes.

Drying by humid heat in a conditioning chamber

The drying occurred in a conditioning chamber in an air stream with parameters adjusted to 60 °C and 17% relative humidity. The closed paper volumes were wrapped in filter paper on both sides and were placed between unglazed ceramic tiles. The volumes were weighted slightly to decrease deformation of the sheets. The drying time for the tested volumes was 6 days.

Drying freely in the open air

The prepared paper samples were dried freely in the open air in the laboratory under normal laboratory conditions. Neither the temperature nor the relative humidity could be adjusted or regulated in the room; however, these parameters were recorded at half-hour intervals. The frozen samples were removed from the freezing box and placed vertically on absorbent filter paper using supports. As soon as possible, the volumes were opened in a fan-like shape to improve drying. The mass decrease in water content was monitored at regular time intervals. The overall drying time was 5-9 days.

Vacuum drying

The vacuum drying method was tested in the operating plant of the Belfor company in France. This equipment is manufactured by Autec Ltd., England. The working volume of the vacuum chamber is 1 m3. The equipment works at a pressure of 5-10 mbar and temperature of 25-30 °C. The chamber is equipped with heated shelves, on which the dried material is placed. The closed paper volumes were placed horizontally on the shelves and cast iron plates were employed as weights to decrease deformation. The water evaporated from the dried volumes is fed through an oil pump, where the oil temperature equals 150 °C. The drying time is dependent on the thickness of the volumes and on the amount of water contained in them. The drying took 5-7 days.

Vacuum packaging

Vacuum packaging of the frozen volumes is carried out in the Archipress equipment, manufactured by the Conservation by Design Ltd., Great Britain, which was donated to the Czech workers by the British Council in Prague. The volume must be packaged in unwoven textile and then covered with a layer of absorbent paper on both sides - preferably filter paper; newspaper can also be used as the outermost layer. This prepared volume is then inserted in a polyethylene bag and placed in the vacuum equipment, where it is preferable to apply a load to the volume. Air is withdrawn from the bag during vacuum drying and the bag is then sealed. During the evacuation, the water migrates from the dried volume to the absorbent papers. The bag must then be cut open, the absorbent material is removed and the entire process is repeated until the volume is dried. Usually, 10 cycles are required. The drying time equals 10-14 days, depending on the thickness of the volume.

Microwave drying

Microwave drying was carried out on the Panasonic II 1400 equipment in the Institute of Chemical Processes of the Academy of Sciences of the Czech Republic.

A filter paper sample was dried for a period of 165 minutes by a microwave power of 350 W. Thawing occurred for 5 minutes at a temperature of - 20 °C to + 15 °C. The actual drying temperature was between + 33 °C and + 90 °C.

Office paper samples were dried for a period of 85 minutes by a microwave power of 350 W. Thawing occurred for 4 minutes at a temperature of - 20 °C to + 40 °C. The actual drying temperature was between + 34 °C and + 85 °C.

Newspaper samples were dried for a period of 30 minutes by a microwave power of 700 W. After 30 minutes, the power was decreased to 350 W and the drying was continued for a further 210 minutes. Thawing occurred for 5 minutes at a temperature of - 20 °C to + 6 °C. The actual drying temperature was between + 6 °C and + 116 °C.

The following table gives the ability of the individual methods to vary the water content of the books during drying. Drying at low relative humidity is fast, but a large difference between the water content on the surface and inside the book is established. At a certain moment, the content of water on the surface is almost zero and the inside of the book is wet or frozen. This leads to considerable and frequently irreversible deformation of the block of the book and the covers. It is necessary to renew the natural water content in the book. This is true of lyophilization, hot air and vacuum drying.

From this point of view, by far the best method is vacuum packaging; in addition, the paper block is compressed by atmospheric pressure and deformation of the paper is not possible.

Drying in the open air is a moderate method from the standpoint of the humidity gradient; however, because it does not permit fixing of the dried material, it is problematic from the standpoint of deformation.

The remaining method, drying with humid air at elevated temperature, is a process that can be readily carried out in existing wood drying equipment. It follows from the subsequent text that there is no acute danger of growth of fungi even for prolonged drying times at elevated humidity. The material can be fixed during drying and thus deformation can be limited. If a suitable temperature and humidity regime is employed, the book has a natural water content following drying.

The behaviour of water during drying is related to the aspect of running of inks and stamps. Liquid water migrates into the drier zones during drying in all the methods with the exception of lyophilization. This water carries soluble substances with it and these substances are then concentrated at the places where the water is vaporized most. Because an increase in temperature mostly also increases the solubility, this effect is greater for thermal methods.

Tab. 2: Humidity regime in paper during drying

|

Drying |

Humidity gradient |

Water content |

Regeneration |

|

Lyophilizace |

large |

0 |

necessary |

|

Vacuum |

large |

0 |

necessary |

|

Vacuum packaging |

minimal |

equilibrium |

not necessary |

|

In the air |

small |

equilibrium |

not necessary |

|

Humid air |

small, adjustable |

equilibrium |

not necessary |

|

Hot air |

large |

0 |

necessary |

|

Microwave |

small |

uncontrollable |

necessary |

Three types of paper were chosen:

Blocks of size A4 containing 60 or 100 sheets were made from filter and office paper. The sheets in the block were numbered at the top and bottom edges and the block was then cut into two halves with size A5. For newspaper, we employed bound volumes of period newspapers and then proceeded in the same way as for filter and office paper, with the difference that the initial size was approximately A3 and the corresponding halves were of size A4. The volumes contained 90 to 110 sheets.

One half of each block was used as a standard characterizing the properties of the initial paper and the second half was immersed (to complete soaking), frozen (temperature of approx. - 20 °C) and dried by one of the tested drying methods. In the subsequent text, these halves will be termed the standard half and the dried half.

In testing the effect of the drying methods on the properties of the paper, each property was tested on identical (corresponding) sheets from the standard and dried halves. Each property was tested on outer and inside sheets of the block, in the direction parallel to and perpendicular to the direction of manufacture of the paper. The properties of the standard half were considered to correspond to 100%.

Here, it should be mentioned that soaking, freezing and subsequent careful drying frequently leads to an improvement in the mechanical properties as a consequence of partial renewal of the inter-fiber bonds and release of internal tension.

2.4.1 Mechanical Properties

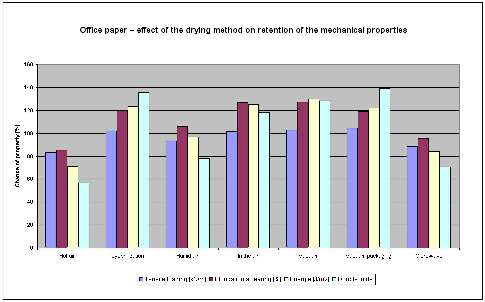

Fig. 1 Office paper - effect of the drying method on retention of the mechanical properties.

Office paper

This paper is used as an example of well-sized, low-absorbance, filled paper. The amount of absorbed water related to the original weight of the dry material equals 50 to 65%. It can be seen from Fig. 1 that, with the exception of methods employing elevated temperatures, the drying does not lead to worsening of the strength properties. To the contrary, there was an improvement in the strength properties that are dependent primarily on the elongation. Hot-air drying slightly decreased the strength of the paper above 80% and the folding resistance below 60%. Drying with humid heat decreased the strength to 90% and the folding resistance to 80%. Microwave drying decreased the value of the tensile loading to about 90% and the folding resistance to 70%.

Fig. 2 Newspaper - effect of the drying method on retention of the mechanical properties.

Newspaper

Newspaper is used as an example of low-sized, highly absorbent, unfilled wood-pulp paper. The amount of water absorbed, related to the original weight of the dry material, equals 165 to 175%. It is apparent from Fig. 2 that the tensile strength is retained for methods employing a vacuum and decreases to 90% for the other methods. The double folding strength decreases significantly to 80% for lyophilization and catastrophically to 15% for the hot-air method. Microwave drying decreased the resistance in folding on an average to 60%; however, these changes are not constant throughout the cross-section of the whole dried block. The resistance in folding of the samples prepared from outer sheets decreased to 80-95%, while this value decreased to 32-34% for the inner sheets. This indicates that the drying process is quite uneven.

Fig. 3 Filter paper - effect of the drying method on retention of the mechanical properties.

Filter paper

Filter paper is used as an example of unsized, highly absorbent, unfilled paper made from unrefined, long-fiber, bleached chemical pulp. The amount of water absorbed, related to the original weight of the dry material, equals 165 to 175%. It is apparent from Fig. 2 that lyophilization greatly damages this material, i. e. is not capable of remedying the damage to the paper structure that occurred during freezing of the material, as the effect of the surface tension of liquid water is lacking. As the fibers are not filibrated and inter-fiber bonds are not developed in this material, drying by the other methods also does not renew the original strength damaged by freezing. The resistance in folding decreases most when using methods employing a vacuum. This decreases below 50% for lyophilization, below 70% for vacuum drying and below 80% for vacuum packaging. The microwave drying method decreases the resistance in folding to 80%.

Evaluation

Hot-air drying significantly decreases some of the mechanical properties of office paper and newspaper (especially the resistance in folding - double folds); in contrast, methods employing a vacuum decrease the mechanical properties of absorbent and unsized paper. From the standpoint of the effect on the mechanical properties of the dried documents, the microwave drying method lies somewhere between the hot-air method and the humid heat method.

Tab. 3 Effect of the drying methods on the chemical properties of the tested papers

|

Drying method |

Office paper |

Newspaper |

Filter paper |

|||

|

Original pH |

pH change |

Original pH |

pH change |

Original pH |

pH change |

|

|

Hot air |

7,35 |

- 0,1 |

3,95 |

- 0,12 |

6,85 |

- 0,3 |

|

Lyophilization |

7,2 |

0,1 |

3,85 |

0,1 |

6,85 |

- 0,35 |

|

60 oC, 17 % rel. hum. |

7,3 |

0 |

4 |

0,2 |

6,8 |

- 0,05 |

|

In the air |

7,4 |

0 |

3,8 |

0,6 |

6,8 |

- 0,05 |

|

Vacuum |

7,6 |

- 0,2 |

4,1 |

0,05 |

6,85 |

- 0,05 |

|

Vacuum packaging |

7,3 |

0,1 |

3,9 |

0,25 |

6,8 |

0 |

|

Microwave drying |

7,92 |

0,27 |

3,75 |

0,17 |

6,97 |

-0,3 |

Tab. 4 Effect of the drying methods on the optical properties of the tested papers

|

Drying method |

Colour change ΔE |

||

|

Office paper |

Newspaper |

Filter paper |

|

|

Hot air |

4,8 |

5,5 |

2,3 |

|

Lyophilization |

0,3 |

1,0 |

0,5 |

|

60 oC, 17 % rel. hum. |

1,4 |

1,4 |

0,2 |

|

In the air |

0,8 |

0,7 |

0,2 |

|

Vacuum |

0,5 |

0,8 |

0,7 |

|

Vacuum packaging |

0,9 |

1,6 |

0,1 |

|

Microwave drying |

0,2 |

2,5 |

0,1 |

A decrease in the pH around a value of 7 is insignificant from the standpoint of the corresponding number of acidic compounds formed and it can be assumed that it is a result of the soaking in water. For newspaper, whose pH varies around a value of 4, a decrease in the pH by 0.1 units is more significant and indicates that hydrolytic degradation may occur during hot-air drying.

A more significant colour change occurs only for the hot-air and microwave methods.

Evaluation

The monitored physical chemical properties of the individual papers practically did not change on drying - with the exception of hot-air drying.

Various types of deformations, that are characteristic for the individual types of drying, appeared during the drying process for all the model volumes.

Hot-air drying

|

Following drying, the outer sheets of the volume of office paper exhibit deformation in the longitudinal direction, deformations in the paper were formed inside the block in the shape of concentric rings (plates). The paper is stained brown at the site of the inserted metal plates and does not exhibit the presence of optical brighteners in UV light.

|

The newspaper volume has highly deformed cardboard covers. The sheets of paper are slightly wavy along the edges and are stained brown to black and are brittle around the entire circumference (to a width of about 1 mm). The sheets of paper adjacent to the metal plates are also stained brown.

|

The filter paper is highly deformed in the entire block. It exhibits deformation in the shape of concentric rings and the waviness extends to the edges of the paper sheets. The edges of the paper are stained brown and the paper is brown over the entire area at the sites of contact with the metal plates.

Note: During drying, the office paper sticks together because of the sizing agent released from the surface sizing.

Lyophilization

|  |  |

The outer sheets of the volume of office paper have modified surface structure (loosened fibers - also confirmed by the strength properties). The inner parts of the block exhibit deformation in the shape of a plate - the place where ice remained the longest.

The deformation of the cardboard covers on the newspapers is small. The outer sheets of the paper block are slightly wavy and exhibit deformation in the shape of rings from the center of the block.

|  |  |

The filter paper exhibits visible changes in the structure of the surface. The surface of the outer sheets is very ruffled and there are occasional blisters. The inner part of the block has deformations in the shape of concentric rings; the ruffling of the fibers on the surface is not as obvious here.

Note: SThe drying occurred in enclosed frozen volumes bound with cord.

Drying with humid heat (60 °C a 17 % relative humidity)

|

The office paper is longitudinally wavy in the entire block.

The newspaper volume has highly deformed cardboard covers. There are deformations in the entire volume from the centers of the sheets in the shape of rings, which are clearest at the edges of the paper surface.

|

The block of filter paper is visibly deformed. The paper sheets are wavy at the edges and exhibit central deformation over the whole surface.

Note: The volumes were fitted with filter paper and fixed between wooden boards.

Dried loose in the air

|

The entire block of office paper exhibits longitudinal waviness. The volume was dried opened into a fan and is thus greatly loosened (change in volume).

The newspaper volume has highly deformed cardboard covers. Longitudinal waviness of the paper is visible in the entire block.

The filter paper exhibits minimal deformations and the surface of the paper is ruffled. The first sheet was damaged in handling. The block is practically not deformed.

Vacuum drying

The whole block of office paper is longitudinally deformed and small blisters are visible on its surface.

The cardboard covers of the volume of newspaper are only slightly deformed. The whole block of paper sheets is longitudinally deformed.

The surface of the filter paper is ruffled. The sheets of paper are slightly wavy along the edges.

Note: The volumes were weighted with cast iron plates during drying.

Vacuum packaging

The block of office paper and the individual papers are free of deformations. The surface of the paper has a visibly coarser structure. After drying, it was very difficult to mechanically separate the sheets.

The volume of newspaper is practically free of deformations. The sheets of paper are bent at the edges because of unsuitable interspacing with the absorbent paper in the packaging equipment. The sheets of paper were separated with relatively great difficulties. Because the paper is fragile, the sheets were sometimes torn.

The block of filter paper is practically free of deformations. The sheets of paper are crushed at the edges because of unsuitable interspacing with the absorbent paper during packaging.

Microwave drying

|

The block of office paper and the individual papers are free of deformations. The individual sheets exhibit slight longitudinal waviness.

|

The volume of newspaper exhibits only slight longitudinal waviness.

|

The block of filter paper is practically free of deformation. The sheets of paper are slightly wavy at the edges.

Comparison of the individual methods from the standpoint of deformations

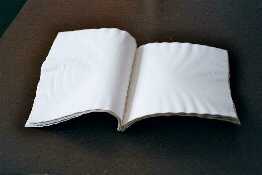

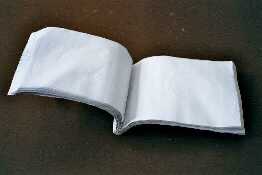

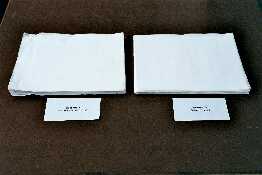

Standard samples of volumes of office paper, newspaper and filter paper. The state with which the samples are compared following soaking, freezing and drying.

|  |  |

Office paper following drying. The methods of drying by lyophilization, vacuum drying and vacuum packaging.

|  |  |

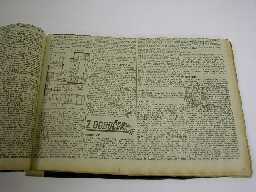

Volumes of newspapers following drying. Drying of the cardboard covers constitutes a problem. Marked deformations are caused by hot-air drying and drying in the open air. Other methods can be accepted and the best results are obtained for vacuum packaging.

|  |  |

The volume of filter paper following drying. All the methods are acceptable except hot-air drying. Drying freely in the air led to mechanical damage as a result of handling during drying.

Note: The method of microwave drying was subsequently included in the set of tested methods. Consequently, this report does not include photographic documentation of deformation changes in the volumes caused by microwaves compared to the other studied methods.

Evaluation

The best results from the standpoint of minimization of deformations were obtained in drying by vacuum packaging and by microwaves. All the other drying methods led to a smaller or larger deformation of the paper block and cardboard covers of the binding.

For some drying methods, it can be assumed that a certain effect will be on micro-organisms, which are present in the flooded written materials in enormous numbers. Of the very broad range of these micro-organisms, we concentrated on those that are detrimental especially for books and archive materials, but less so for human beings. Two kinds of common fungi, members of the genera Penicillium and Aspergillus, were selected and the paper was infected with these spores. Because favorable conditions for the germination and growth of fungi could occur in some of the drying methods (drying in the open air or at slightly elevated temperatures), we monitored the number of spores and any growth under a microscope. On the other hand, it could be assumed that the other methods would tend rather to have a negative impact on or could even be fatal for fungus spores (very low or high temperatures, decreased pressure); in this case, cultivation must be carried out on a nutrient medium that clearly differentiates between living and nonliving spores.

Material and Methods

Micro-organisms

Samples

Procedure

Books with a thickness of approx. 1 cm were manufactured from office paper. All the tested types of paper were fixed both on the surface of the books and inside the book blocks. These books were immersed in water from the water mains, infected with fungus spores (each type of paper was infected three times with a culture of Aspergillus niger and three times with a culture of Penicillium notatum), were frozen and then finally dried using various methods.

Following drying, all the samples were first viewed under a microscope to determine whether fungus grew during the drying. Then squares of paper with dimensions of 2x2 cm were cut out from the infected places and were placed on the surface of malt wort nutrient agar. Incubation took place at 24 ± 4 ´C for a period of 14 days. The growth of the fungus was monitored during this period of time.

Results

Growth of fungus during the drying was not observed in any case.

The ability of fungus spores to survive the less favorable conditions during drying is summarized in the following table (Table 5) and graph (Fig. 4). Letters A and P denote the cultures of the Aspergillus and Penicillium fungi, which survived after completion of the whole process.

Tab. 5 The effect of the drying methods on the survival ability of fungus spores

|

Hot air |

Lyophilization |

Damp heat |

In the air |

Vacuum |

Vacuum packaging |

Microwave |

|

|

FIL 1 |

- - - - - P |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAA - - P |

- - - - PP |

|

FIL 2 |

- - - - - - |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAAPPP |

- - - - - - |

|

PAP 1 |

- - A - - P |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAA - PP |

- - - - - P |

|

PAP 2 |

- - - - - - |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAAPPP |

- - - - - - |

|

NOV 1 |

- - - - PP |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

- AA - - - |

- - - PPP |

|

NOV 2 |

- - - - - P |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAAPPP |

- - - - PP |

|

ŠKR 1 |

- - A - - - |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAAPPP |

- - - - - - |

|

ŠKR 2 |

- - - - - - |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAAPPP |

- - - - - - |

|

KLI 1 |

- - - PPP |

AAAPPP |

- - - - - P |

AAAPPP |

AAAPPP |

AAAPPP |

- - - - - - |

|

KLI 2 |

- - - - - - |

AAAPPP |

- - - - - - |

AAAPPP |

AAAPPP |

AAAPPP |

- - - - - - |

|

| ||||||||||||||||||||||||||||

Discussion

Under the experimental conditions, fungus did not grow during the drying in any of the cases. In a real situation, where micro-organisms are present on the paper in the active state following the floods, this cannot be completely excluded.

The detrimental effect of the drying methods on fungus spores has been demonstrated only for methods employing higher temperatures. While the effect of the relatively high temperature of 115 °C is quite understandable, the same effect at much lower temperatures (60 °C) can be explained by the simultaneous action of high humidity, which activates the spores. In this condition, the spores are far more sensitive to the action of external factors and thus this relatively low temperature is sufficient to kill them. Similarly, microwave radiation has a detrimental effect on fungus spores, although the period of action of the higher temperature is relatively short in this case.

A certain impact on fungi, although much smaller, was also observed in drying employing vacuum packaging. Repeated changes in the pressure killed part of the spores and the others that survived grew more slowly.

These results are fully valid only for the above fungus strains Aspergillus niger and Penicillium notatum. Fungi that are more or less resistant can also be present.

Fig. 4 Fraction of viable fungus spores following drying.

Evaluation

In is not possible to rely on automatic killing of the micro-organisms present during drying of archive materials and books affected by the floods. Only methods employing higher temperatures constitute an exception - however, these methods simultaneously cause considerable damage to the paper and thus their use is limited. Thus, effective disinfection must necessarily follow drying in the other cases.

The results of this study cannot be used automatically for other types of materials than those tested here (e. g. photographs, tracing paper). This aspect will be studied in later stages.

Comments of the authors of the study

| PhMr. Bronislava Bacílková | State Central Archives in Prague |

| Dr. ing. Michal Ďurovič | State Central Archives in Prague |

| Ing. Jiří Neuvirt, CSc. | Chemtech, Praha |

| Ing. Hana Paulusová | State Central Archives in Prague |

| PhDr. Jiří Polišenský | National Library of the Czech Republic, Prague |

| Ing. Magda Součková | National Library of the Czech Republic, Prague |

| Roman Straka | State Central Archives in Prague |

| Ing. Jitka Šimečková | National Library of the Czech Republic, Prague |

| Jiří Vnouček | National Library of the Czech Republic, Prague |

| Ing. Lucie Weberová | State Central Archives in Prague |

| Ing. Milan Hájek | Institute of Chemical Processes, Academy of Sciences of the Czech Republic |

| Mgr. Martin Hrubeš | State Central Archives in Prague |

© State Central Archives in Prague

Last change this page - 2003, January

Pozor! Nacházíte se v archivu starých webových stránek Národního archivu. Aktuálnost informací ani validita zdrojového kódu nejsou zaručeny! Pro přístup k aktuálním webovým stránkám Národního archivu klikněte sem.